Temp

Machine and Technologies

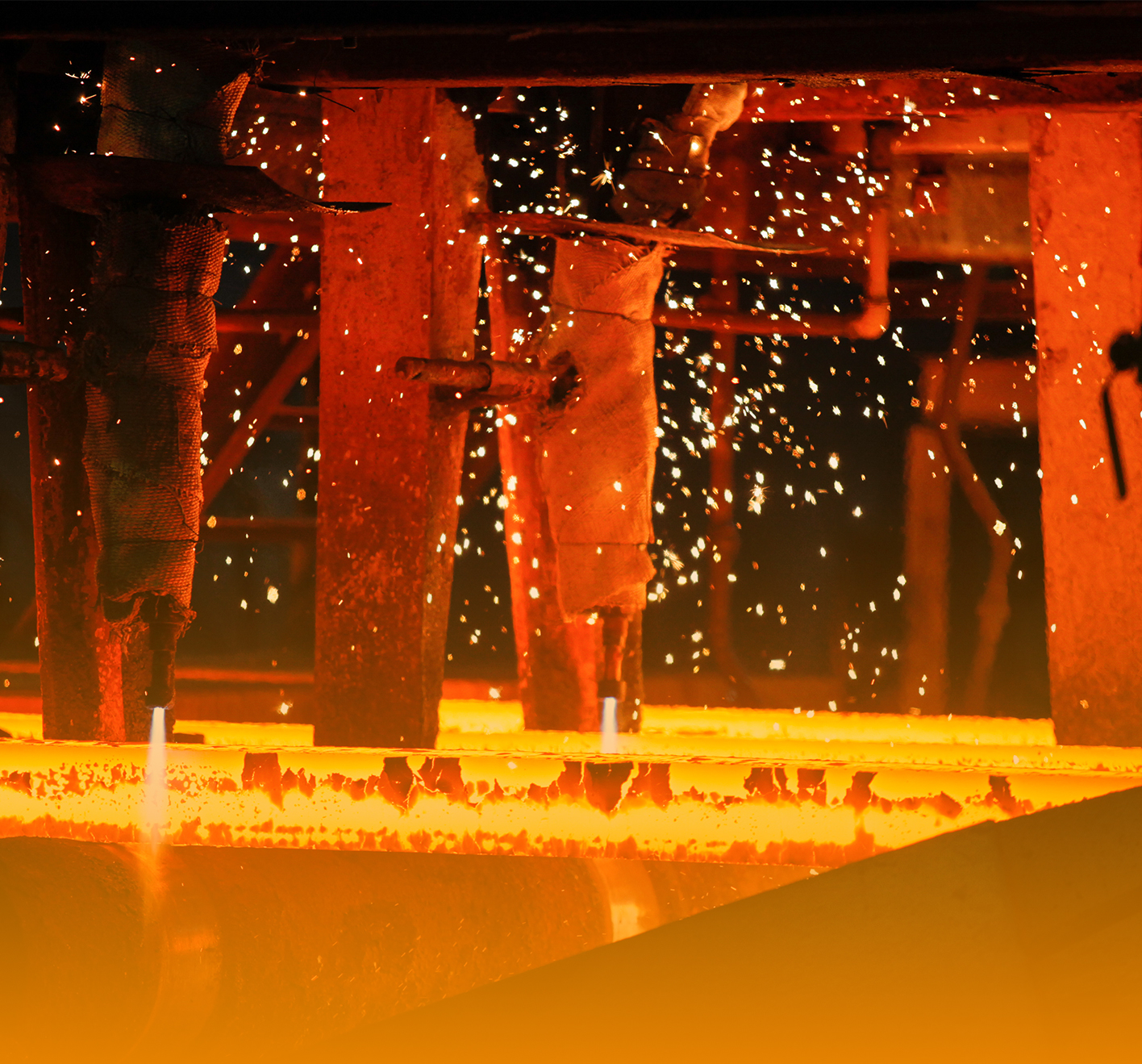

HEAT TREATMENT

Heat treatment enables the desired properties of the material to be obtained by changing the structure of alloys in a controlled process. Within our company, we are capable of performing solution heat treatment and aging, tempering, quenching, annealing, recrystallization, normalization, and soft annealing heat treatments. The alloy groups we work with include aluminum alloys, steel alloys, magnesium alloys, titanium alloys, and superalloys.

MACHINING

Thanks to the advanced machinery infrastructure, Temp Makine provides services to sectors requiring high precision, such as aviation, defense industry, and machine spare parts. We have the ability to process difficult-to-machine raw materials like superalloys with high precision and within narrow tolerance ranges.

ADVANCED MANUFACTURING PROCESSES

It is aimed to obtain various products with complex part geometry, hard and brittle materials and tool wear that cannot be produced through traditional production methods with advanced manufacturing methods such as additive manufacturing, wire erosion and plunge erosion.